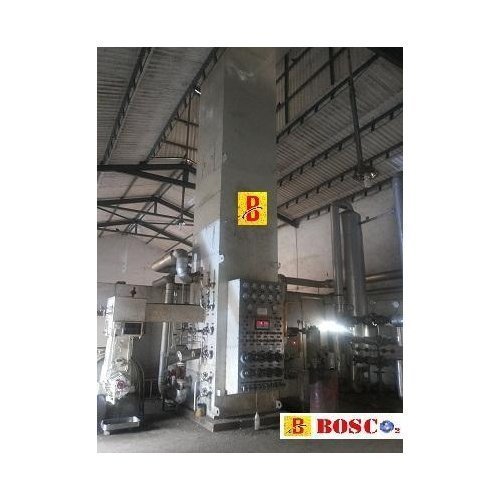

Automatic Oxygen Plant

Product Details:

- Product Type Oxygen Generation Plant

- General Use Industrial Oxygen Production

- Material Mild Steel

- Type PSA (Pressure Swing Adsorption)

- Capacity 20 Nm3/hr to 200 Nm3/hr

- Computerized Yes

- Automatic Yes

- Click to View more

Automatic Oxygen Plant Product Specifications

- Yes

- Customized as per model

- Approximately 7.0 Nm3/Nm3 O2

- Yes

- Varies with capacity

- 20-200 Nm3/hr

- 5-7 Bar

- Mild Steel

- Up to -60C

- Industrial Oxygen Production

- Oxygen Generation Plant

- PLC Based

- Air Cooled

- PSA (Pressure Swing Adsorption)

- 8 - 30 kW (depending on model)

- Blue & Silver

- 933%

- 20 Nm3/hr to 200 Nm3/hr

- 380-440 V

- Skid Mounted, Low Power Consumption, Low Maintenance

Product Description

Facilities that demand oxygen for their processes often install an automatic oxygen plant. This plant through the process of air separation produces oxygen. It uses ambient air to separate oxygen by following a technology called Pressure swing adsorption (PSA). As the plant is equipped with sensors and control systems, all its tasks are performed automatically. Through continuous monitoring, it automatically adjusts the parameters when required to ensure performance. The oxygen produced by this industrial plant is used in medical facilities, steel manufacturing, chemical production, and other industrial applications.

This industrial system is used in several industrial sectors along with many technological processes. The industrial processes in which the oxygen generated by this plant is used are as follows:

- Metal processing

- Welding

- Cutting

- Brazing

- Chemical reactions

- Glass manufacturing

- Waste management

- Chemical

- Petrochemical

- Oil & gas

- Medicine

Reliable PSA Oxygen Generation for Industry

Harnessing PSA technology, this oxygen plant ensures consistent and high-purity oxygen supply, tailored for industrial use. Built on a robust mild steel frame, it features digital controls and automated safety systems. The air-cooled, skid-mounted unit supports fast positioning and commissioning, offering a practical solution for continuous production needs. Low power consumption and auto-calibration cut down operational costs and minimize intervention, optimizing performance for long-term, large-scale usage.

Precision Operation and Low Maintenance

The plant is engineered for automated, user-friendly operation, managed via a PLC-based digital interface. Start-up is swift at only 15-20 minutes, with low noise and dependable air quality. Auto-calibration ensures ongoing accuracy, while integrated safety sensors and valves maximize workplace safety. Its modular, customizable design and availability of spare parts guarantee seamless integration and reduced downtime for maintenance or upgrades.

Flexible Installation with Export Readiness

Supplied skid-mounted and export-packed in strong wooden cases, installation is efficient and adaptable to specific site requirements. With dimensions and weight customized per model, the plant meets varying spatial and capacity demands. Operating within a moderate temperature range and voltage compatibility (380-440 V), it is suitable for diverse industrial settings in India and abroad. Full after-sales support, including spare parts, further assures long-term operational stability.

FAQ's of Automatic Oxygen Plant:

Q: How does the PSA (Pressure Swing Adsorption) process work in this automatic oxygen plant?

A: The PSA process separates oxygen from atmospheric air by passing compressed air through molecular sieves, selectively adsorbing nitrogen and allowing concentrated oxygen to flow out. This ensures high-purity (933%) oxygen production continuously, tailored for industrial applications.Q: What are the installation requirements for the skid-mounted oxygen plant?

A: Installation is straightforward due to its skid-mounted design, requiring a stable foundation, appropriate electrical supply (380-440 V), and connection to an air source. The compact, modular build enables placement in diverse industrial environments with minimal site preparation.Q: When is routine maintenance required for the oxygen plant, and how is it managed?

A: Routine maintenance is minimal, thanks to the plant's robust construction and auto-calibration feature. Periodic checks on filters, compressors, and safety valves are recommended as per the supplier's guidelines. Spare parts are readily available to support ongoing maintenance needs.Q: Where can this automatic oxygen plant be used most effectively?

A: This oxygen plant is ideal for a range of industrial settings where consistent and reliable oxygen generation is essential, such as manufacturing, chemical processing, metallurgy, and healthcare. Its wide operating temperature and pressure range ensure adaptability to diverse site conditions.Q: What are the main operational benefits of a computerized, PLC-based control system?

A: The PLC-based control system delivers precise, automated management of the plant, allowing real-time monitoring, reduced human intervention, and fast detection of system parameters. This enhances user convenience, operational stability, and safety throughout its service life.Q: How is the safety of operators ensured during the plant's operation?

A: Operator safety is prioritized with comprehensive safety features, including built-in safety valves and sensors that monitor pressure and other critical systems. The plant's low noise level and protective packaging further contribute to a safe operating environment.Q: What are the advantages of choosing a skid-mounted, air-cooled oxygen plant for export or industrial use?

A: Skid-mounted, air-cooled designs simplify installation and relocation while reducing water usage. Export packaging in wooden cases ensures safe transit. The system's flexibility, power efficiency, and low maintenance make it suitable for global industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese