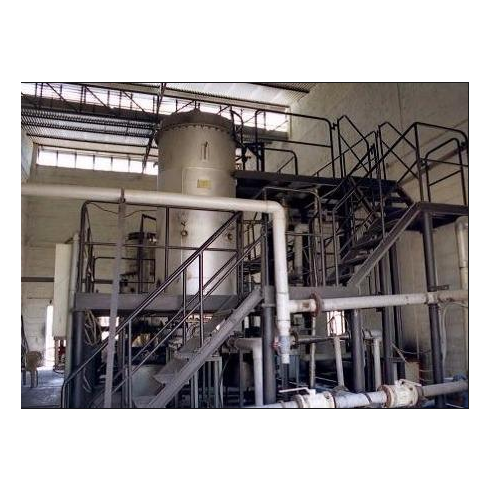

Charcoal Based Carbon Dioxide Plant

Product Details:

- Product Type Charcoal Based Carbon Dioxide Plant

- General Use Production of Carbon Dioxide Gas from Charcoal

- Material Mild Steel (MS)

- Type Gas Generation Plant

- Capacity 500-5000 Kg/hr

- Purity(%) 99.99%

- Production Rate 0.5 to 5 Ton/hr

- Click to View more

Charcoal Based Carbon Dioxide Plant Price And Quantity

- 1 Unit

- 3500000 INR

Charcoal Based Carbon Dioxide Plant Product Specifications

- Up to -60C

- Customizable, Depends on Process Design

- Yes

- Charcoal Based Carbon Dioxide Plant

- Gas Generation Plant

- Customizable as per Plant Capacity

- Mild Steel (MS)

- Industrial Grey / Custom

- 15-20 Bar (Operating)

- PLC Based Automatic Control Panel

- Production of Carbon Dioxide Gas from Charcoal

- 99.99%

- Yes

- Depends on Design (Typically 1500-10000 kg)

- 15-50 kW

- 0.5 to 5 Ton/hr

- Low Maintenance, High Efficiency, Eco-Friendly Operation

- 500-5000 Kg/hr

- 380-440 V

Charcoal Based Carbon Dioxide Plant Trade Information

- Per Month

- 4 Months

Product Description

The Charcoal-Based Carbon Dioxide Plant utilizes innovative technology to convert biomass into high-quality charcoal, effectively capturing carbon dioxide in the process. This sustainable solution reduces greenhouse gas emissions while producing valuable charcoal for energy and industrial applications. Designed for efficiency and low environmental impact, the plant features advanced filtration and gas management systems, ensuring optimal performance. By promoting a circular economy, this plant not only addresses climate change but also supports local economies through green job creation.

Charcoal Based Carbon Dioxide Plant

Product details

|

Purity |

99.96% |

|

Automation Grade |

Automatic |

|

Brand |

Bosco |

|

Usage/Application |

Industrial |

Specification

- Automatic Grade: Automatic

- Condition: New

- Motor: Siemens & ABB

High Recovery and Eco-Friendly Performance

Achieve up to 98% recovery efficiency while maintaining low water consumption, thanks to a closed-loop design and advanced burner technology. The plant operates with hardwood or biomass charcoal, supporting sustainable and eco-conscious production practices.

Versatile Applications Across Industries

This CO2 generation plant supports multiple industries, including beverages, water treatment, chemicals, and agriculture. Customizable feed sizes, continuous/semi-continuous operation, and adjustable capacity enable seamless integration into various manufacturing and processing environments.

Integrated Safety and Automated Control

Equipped with emergency shutdown systems, gas leak detectors, and safety valves, the plant prioritizes operational safety. The computerized PLC-based automatic control panel ensures precise monitoring and control for trouble-free, efficient operation.

FAQs of Charcoal Based Carbon Dioxide Plant:

Q: How does the Charcoal Based Carbon Dioxide Plant produce CO2 gas?

A: This plant generates carbon dioxide by thermally processing hardwood or biomass charcoal in either direct or indirect fired burners. The resulting CO2 is then purified, cooled, and collected in a closed loop, yielding high purity gas for industrial use.Q: What are the benefits of using a closed loop system in this plant?

A: A closed loop system minimizes water consumption and reduces environmental impact by recycling process streams. It enhances efficiency and ensures consistent CO2 purity, resulting in eco-friendly and cost-effective production.Q: When is on-site support provided for installation and maintenance?

A: On-site support is offered during the plants installation phase to ensure correct setup and commissioning. Additionally, ongoing maintenance and spare parts services are available throughout the plants lifespan to keep operations running smoothly.Q: Where can this CO2 plant be used?

A: This gas generation plant is suitable for deployment in the beverage, water treatment, chemical processing, and agricultural sectors. Its versatile design allows integration into diverse industrial settings with customizable dimensions and capacities.Q: What safety features are included in the plants design?

A: The system incorporates several safety mechanisms, including emergency shutdown capabilities, gas leak detectors, and safety valves, all designed to prevent hazardous incidents and protect operators during continuous and semi-continuous operation.Q: How does the computerized control system improve operation?

A: The PLC-based automatic control panel enables real-time monitoring, precise process adjustments, and efficient management of operational parameters, leading to high reliability, minimal maintenance, and stable production efficiency.Q: What is the typical operational life and capacity range of the plant?

A: Designed from mild steel for durability, the plant has a life expectancy exceeding 15 years. It supports a production capacity from 500 to 5,000 kg/hr (0.55 ton/hr), suitable for small to large-scale industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese