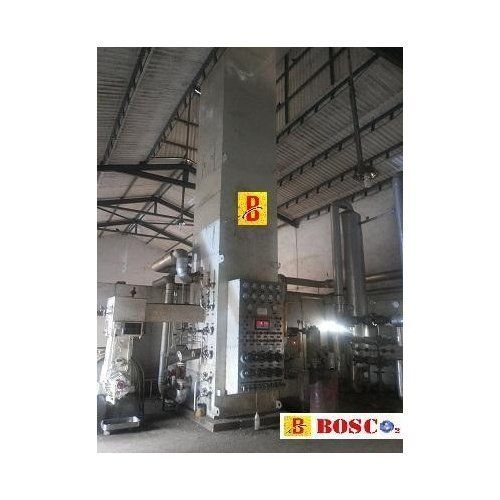

CO2 plant biogas based

Product Details:

- Product Type CO2 Plant (Biogas Based)

- General Use Industrial Use (Food & Beverage, Welding, Fire Extinguishers, etc.)

- Material Mild Steel

- Type Biogas to CO2 Generation Plant

- Capacity 100-1500 Kg/Hr

- Computerized Yes

- Automatic Yes

- Click to View more

CO2 Plant Biogas Based Specification

- Depends on Plant Capacity

- Compact design, Skid mounted, Continuous operation

- Yes

- PLC Based Control Panel

- Up to -60C

- 100-1500 Kg/Hr

- Varies as per capacity

- Biogas to CO2 Generation Plant

- Chilling Plant & Water Cooled Condensers

- Yes

- CO2 Plant (Biogas Based)

- Industrial Grey/Blue

- 99.99%

- Approx. 40-250 kW

- Industrial Use (Food & Beverage, Welding, Fire Extinguishers, etc.)

- Mild Steel

- 440 V / 3 Phase / 50 Hz

- 15-20 Bar

- Customized Design

- Customized as per requirement

- Integrated Scrubber & Filters

- On-site and Remote Monitoring Available

- Fully Automatic

- <70 dB

- Food & Beverage Grade, Medical Use, Industrial Gases

- 20 Bar (max)

- Flameproof Motors, Pressure Relief Valves

- CO2 Cylinder Filling System, Storage Tank Available

- 30-60 Minutes

- Amine Scrubbing/Absorption

- 2-3 Months

- Biogas (from Agricultural & Organic Waste)

- Meets International Standards

- Low Maintenance, Annual Service Recommended

Product Description

Capturing co2 from biogas can bring about poor co2 emission. Depending on how biogas is applied, there are one-of-a-kind routes to seize co2. A biogas plant that uses raw biogas to provide power and warmth can be retrofitted by way of integrating co2 seize.

FAQs of CO2 Plant Biogas Based:

1. What happens to co2 in biogas?

Ans. The residual co2 from the biogas manufacturing which might have been emitted into the atmosphere is now captured, reused and included right into a round financial system machine. The biogas plant operates especially on livestock manure, deep clutter from stables, organic waste from industry and retail and a small quantity of electricity vegetation.

2. How much co2 is in biogas?

Ans. Biogas incorporates roughly 50-70 percent methane, 30-40 percent carbon dioxide, and trace quantities of other gases.

3. How do you extract co2 from biogas?

Ans. Biogas may be upgraded for getting rid of co2 through the use of six principal technologies: cryogenic separation, membrane separation, organic bodily scrubbing, chemical scrubbing, strain swing adsorption, and high-pressure water scrubbing.

Advanced Amine Scrubbing for Reliable CO2 Recovery

Our biogas-to-CO2 plant utilizes efficient amine scrubbing/absorption to capture and purify CO2 directly from biogas generated via agricultural and organic waste. This highly effective method ensures exceptional purity, with output suited for stringent food, beverage, and medical-grade requirements. Integrated emission scrubbers and filters guarantee compliance with international environmental norms.

Turnkey, Fully Automated Operation

Benefit from a fully automatic system managed by a modern PLC-based control panel. With computerized monitoring, flameproof motors, pressure relief valves, and extensive safety interlocks, operational reliability is maximized. The compact skid-mounted setup allows for quick installation (2-3 months), and continuous operation ensures consistent CO2 supply for your processes.

Customized Solutions for Diverse Industries

With customizable capacities (100-1500 kg/hr), our CO2 plants are tailored to suit diverse industrial demands-whether for food and beverage carbonation, welding applications, fire extinguishers, or healthcare. The plant produces CO2 at 99.99% purity, boasts a dew point up to -60C, and is delivered with optional accessories like a filling system and storage tank. Remote and on-site service support keeps your operations running smoothly.

FAQ's of CO2 plant biogas based:

Q: How does the amine scrubbing process in this CO2 plant work?

A: Amine scrubbing involves passing biogas through a solution containing amines, which selectively absorb carbon dioxide. The absorbed CO2 is then separated from the amine solution, purified, and compressed to the desired pressure for further use. This process results in high-purity CO2 suitable for sensitive applications.Q: What types of feed gas can be used with this biogas-based CO2 plant?

A: This plant is specifically designed to process biogas derived from agricultural and organic waste. Such sources generate biogas rich in methane and carbon dioxide, which the plant efficiently separates and purifies for industrial CO2 applications.Q: When and where can the CO2 generated by this plant be used?

A: The high-purity CO2 output is suitable for use in food and beverage production, medical facilities, industrial processes like welding, and for filling fire extinguishers. The plant's flexibility makes it ideal for both on-site industrial facilities and centralized gas suppliers.Q: What are the main benefits of using a biogas-based CO2 plant over traditional CO2 sources?

A: Utilizing biogas as a feedstock promotes sustainability by recycling agricultural and organic waste. The process also ensures lower emissions, reduces environmental impact, and produces CO2 at excellent purity levels needed for stringent standards. Additionally, the plant features low maintenance, fully automated operation, and robust safety measures.Q: How long does installation and startup take for this plant?

A: Installation typically requires 2 to 3 months from site preparation to commissioning, thanks to the plant's compact, skid-mounted design. After installation, the plant can achieve operational readiness within 30 to 60 minutes of startup.Q: What is included in the plant's maintenance and service support?

A: The CO2 plant is engineered for low maintenance, with an annual service recommended for optimal performance. Comprehensive service support includes both on-site technical assistance and remote monitoring to ensure smooth, uninterrupted operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese