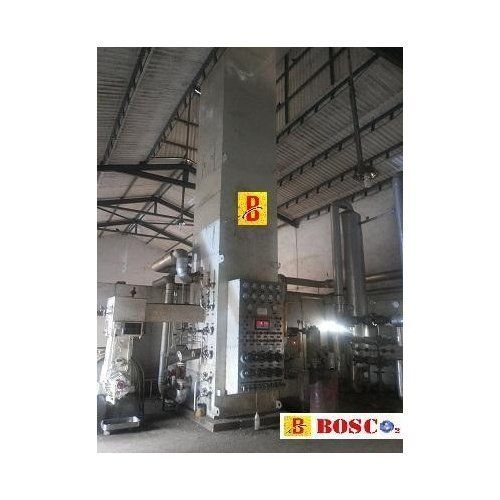

Oxygen Filling Plant

Product Details:

- Product Type Oxygen Filling Plant

- General Use Industrial Oxygen Cylinder Filling

- Material Stainless Steel

- Type Skid Mounted

- Capacity 100 to 500 cylinders/day

- Computerized Yes

- Automatic Yes

- Click to View more

X

Oxygen Filling Plant Product Specifications

- Low maintenance, High reliability

- 5800 kg

- Oxygen 99 Nm/h

- PLC Based

- Stainless Steel

- Skid Mounted

- Industrial Oxygen Cylinder Filling

- -60C

- 100 to 500 cylinders/day

- Yes

- White & Blue

- Yes

- 5500mm x 2250mm x 2400mm

- Water/Air Cooling

- 99.7%

- 150-200 Bar

- 45 KW

- Oxygen Filling Plant

- 380-415 V

- 20 Nm/min

Product Description

BOSCO INDIA Is manufacturing and exporting oxygen nitrogen cylinder filling flowers of all sizes starting from 20 m3/hr to ten,000 m3/hr. Our oxygen/nitrogen gasoline vegetation produces oxygen as well as nitrogen with a purity of ninety-nine. 7% and ninety-nine. Ninety nine% respectively. Our organization has CE iso certification for generating high best vegetation. Our plants fill in cylinders thru liquid oxygen pump generation at well known 155- 160 kg/cm2.

Frequently Asked Questions:

1. What is an oxygen plant in the hospital?

Ans. Containerized vegetation is set up in a delivery container that can be installed out of doors at a health center. Once installed, each plant can straight away supply oxygen to patients via cylinders located at their bedside, which are then again to the plant to be refilled.

2. How do you start an oxygen plant?

Ans. The way to set up an oxygen-filling plant in India? Demand and market analysis of industrial and clinical gases. Licenses to be procured to set up an oxygen production plant.

- Incorporation certificates.

- Extra submit-incorporation certifications for the oxygen filling plant.

3. How tons space do oxygen plants need?

Ans. Oxygen flowers are designed to supply six hundred cylinders in a day. Other than the required area of 14m x 15m, the machine plays cylinder filling at 155 - 200 bar. The skid setup model and pre-packaged air separation unit make the installation faster and hurdle free.

Superior Oxygen Purity and Reliability

This plant delivers oxygen with a consistent purity of 99.7%, making it suitable for critical industrial operations. Its oil-free compressor technology ensures the oxygen is contaminant-free, while the self-lubricating mechanism reduces maintenance requirements. Each unit undergoes rigorous quality control, ensuring steady performance across diverse environments.

Fully Automated and User-Friendly Operation

The PLC-based control system allows for seamless operation, offering both fully automatic and manual modes. This flexibility improves operational efficiency and minimizes manual intervention, accommodating a wide range of industrial needs. Easy interface access and multi-cylinder filling capability enable operators to safely manage high cylinder outputs with minimal training.

FAQ's of Oxygen Filling Plant:

Q: How does the Oxygen Filling Plant ensure a consistent oxygen purity of 99.7%?

A: The plant utilizes advanced filtration and oil-free compressor technology, coupled with a robust PLC-based control system, to maintain a steady oxygen purity of 99.7%. Each filling cycle incorporates quality assurance protocols to prevent contamination and assure purity standards.Q: What is the typical installation and commissioning process for the Oxygen Filling Plant?

A: Installation of the plant typically takes between 2-4 weeks. The process includes site preparation, assembling the skid-mounted unit, connecting all utilities, and thorough system testing. Trained engineers oversee commissioning to ensure smooth integration with your operations.Q: When is the Oxygen Filling Plant ready for operation after startup?

A: The plant achieves operational readiness within 30 minutes of startup. This includes system checks, stabilization of operational parameters, and readiness for cylinder filling-enabling a quick response to industrial oxygen demands.Q: Where can this Oxygen Filling Plant be installed?

A: Thanks to its ambient temperature tolerance of -10C to +50C and compact, skid-mounted design, the plant can be installed in diverse industrial locations across India and globally, provided proper site and utility requirements are met.Q: What steps are involved in the oxygen cylinder filling process?

A: The process involves compressing purified oxygen through an oil-free compressor, reaching a filling pressure of up to 150 bar. Cylinders are connected to the multi-cylinder ramp, filled automatically or manually, and monitored electronically for safety and efficiency using the PLC-based system.Q: How is the plant beneficial for high-demand industrial applications?

A: With an output capacity of 100 to 500 cylinders daily, rapid start-up, and low maintenance requirements, the plant offers a dependable oxygen supply. Its high reliability, low noise operation, and flexible controls make it an ideal solution for continuous industrial use.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese